Awarded STSMs

| CALL 9.0

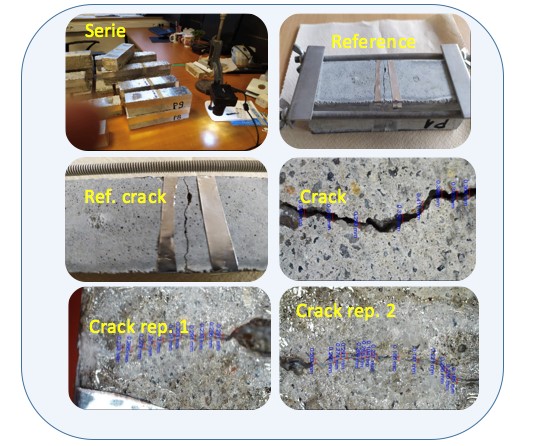

Applicant: Claudio Larosa

STSM Topic: A comprehensive study of polycarbonate barriers properties loading graphene in small cracks concrete repair

Host: Riga Technical University, Riga (LV)

Period: 26/10/2020 to 09/11/2020

Work Plan Summary:

The intention was to examine the macroscopic-microscopic effects of graphene Go embedding in a thermoplastic polymer on the fracture interface in use as self-rehabilitation. The macroscopic structure is always slowly undergoing progression, which received remarkable influence from the environment’s corrosive agents. Concrete cracks repaired have a stabilizing period of one day;; after this relaxing time-lapse, modifications in composites are irreversible, while concrete can still re-structured itself developing into further modification on bulk, but also at the interface with dynamic crystal growth. The ultimate aim is to prove evidence of a new network between graphene on the polycarbonate surface and dynamic microstructure in concrete. The trick to being solved lies in evaluating and following macroscopic phenomena mainly induced by graphene Go in polycarbonate and its consequence role on the crack’s repair. On the other hand, graphene can stabilize polycarbonate as an optical filter and change its mechanical properties. Because of the increasing interest in graphene within the far-reaching project flagship, the focus was shifted to graphene’s scale-up process. This production will provide a crucial amount on a vast scale of powders, availability for wholesale use makes the release of this material for other house building or infrastructure purposes. therefore, it requires a conspicuous graphene amount for loading manufacture. Thus, graphene is an inertness mesh structure with grid defects and size dimensional to the limit between nano to micro-scale with well-known stability behavior of their dispersion

derivatives. While nano noble and lanthanide particles have a high surface area with very few amount quantities available from synthesis, graphene promises to be realized on a large scale without the well- known aggregation and desegregation effects of composites. Noteworthy on this point, graphene maintained its structure in a medium solvent. Composites stability in cracks were tested, and this means that the chloroform/polycarbonate ratio as logical viscosity was checked to the fixed appropriate reference value for multiple doping. Cracks stability was tested;; no polycarbonate crystallize effects were observed during preparing healing cracks, while in concrete the growing crystal growth was quick to be observed. The crystalline waterproof growth effect at the interface is the study’s motive within its heterogeneous matrix structure. The flood test is under evaluation on concrete cracked composites. Solutions were produced extemporaneously as alternative solutions because of repetitive viscosity change from top to bottom of the flask tube. The controlled micro crack in concrete is presented using viscous composite solutions, which is considered a reinforced material with barrier and adhesive properties. We considered graphene Go a promising material to stabilize and arrest the crack evolution in concrete.

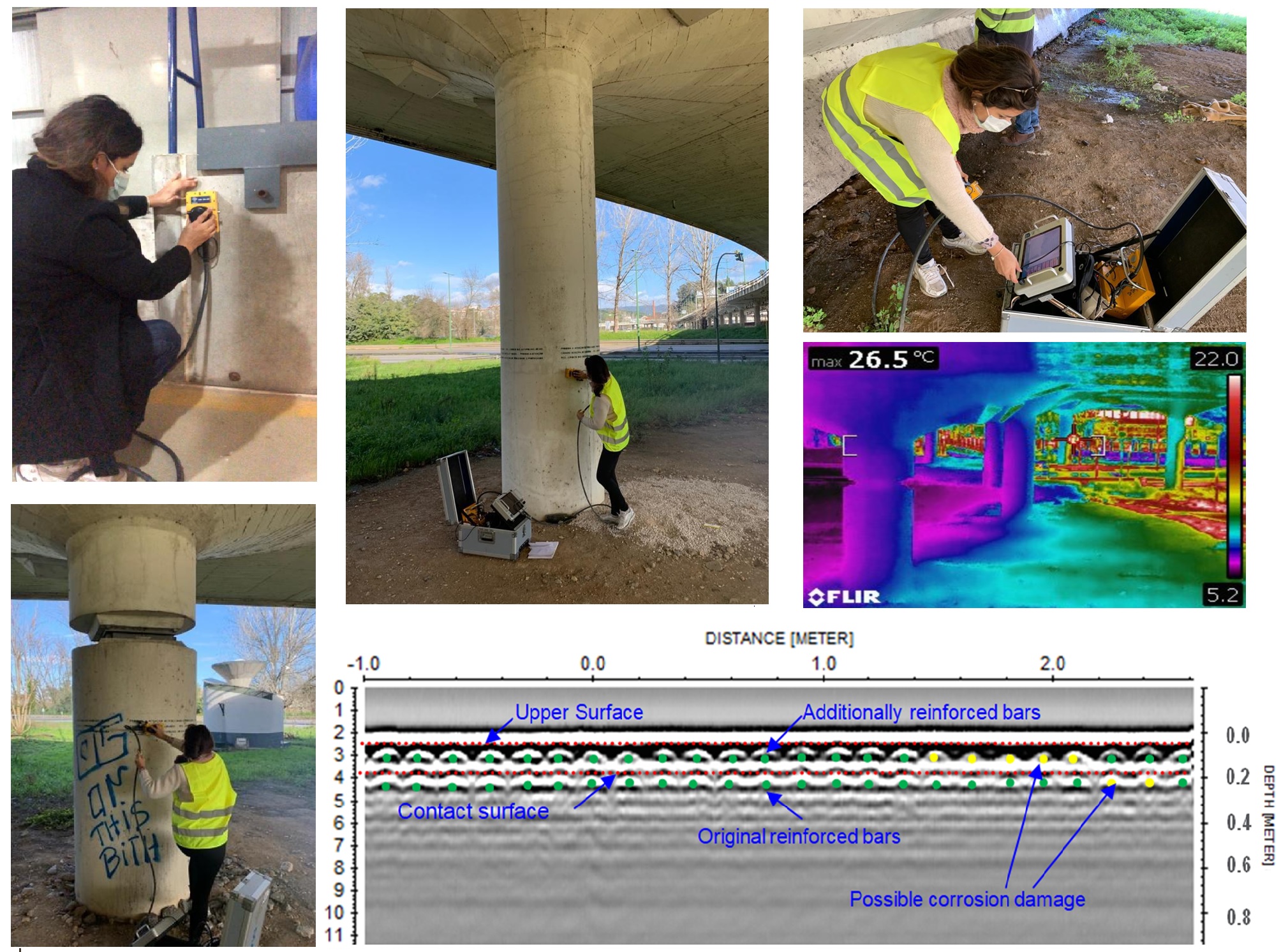

Applicant: Viviana Alejandra Sossa Arancibia

STSM Topic: Using NDT techniques for assessing the implementation of preventive repair activities on reinforced concrete bridges

Host: Jose C. Matos, University of Minho, Braga (PT)

Period: 1/12/2020 to 04/01/2021

Work Plan Summary:

In this STSM, it was proposed the application of NDT for evaluating the performance of preventive repair techniques used in existing reinforcing concrete bridges. For this aim, Ground Penetration Radar (GPR) was used as the main assessment technique. The NDT was applied to a prestressed reinforcing concrete bridge, belonging to Infraestruturas de Portugal (IP), previously submitted to preventive repair works. is important to follow up on the repair activities, carried out to verify the condition and performance of existing structures. Non-destructive techniques (NDT) are a useful tool when evaluating or monitoring those repairs. In this case, the obtained results have been satisfactory. Indeed, the analysis of the repair activities, carried out ten years ago. The GPR results clearly show the two reinforcement bars layers. The first one corresponds to the wrapping, while the second one belongs to the old column. In some horizontal bars it was detected a change of the amplitude, which may indicate a possible damage on these reinforcements or possible corrosion damage. In the vertical radar line the longitudinal bars are more clearly seen than in the transversal radar line. The depth of the wrapping can be validated (around 17cm). The contact surface generated between the old column and the wrapping is uniform, being no significant cracks and cavities detected. The thermographic camera images did not show large cracks, or moisture, as the existing cracks were almost imperceptible.